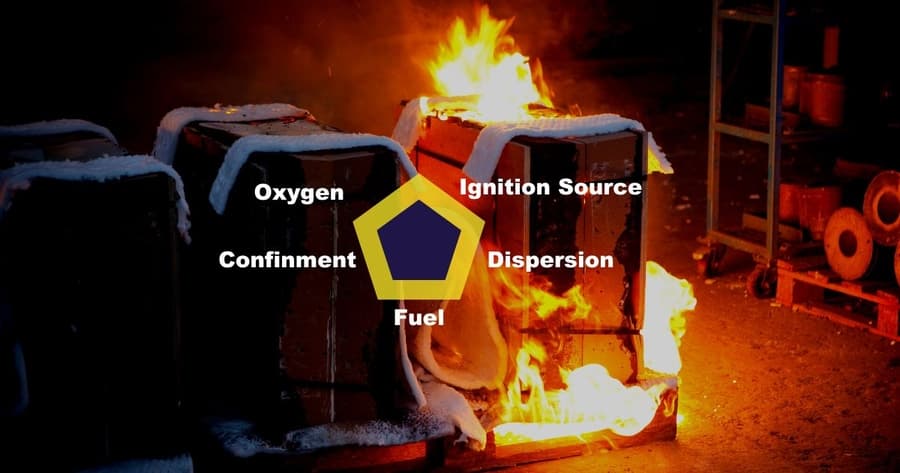

Industrial safety experts are emphasizing the importance of understanding the Dust Explosion Pentagon as a crucial step in preventing catastrophic incidents in workplaces. This concept, which outlines the five essential elements required for a dust explosion to occur, is gaining renewed attention as industries seek to enhance their safety protocols. The Dust Explosion Pentagon identifies five key components that must be present simultaneously for a dust explosion to take place: fuel in the form of a dust cloud, oxygen, an ignition source, dispersion of dust particles, and confinement. Each of these elements plays a critical role in the formation and propagation of a dust explosion.

Combustible dust particles suspended in the air serve as the fuel for these explosions. This can include various materials such as wood, metal, plastic, or organic substances that have been ground into fine particles. The presence of oxygen, which is typically abundant in most industrial environments, is necessary for combustion to occur. An ignition source, which could be a spark, flame, or heat source, provides the initial energy to start the combustion process. The dispersion of dust particles into a cloud increases the surface area exposed to oxygen, making the mixture more volatile. Finally, confinement in a closed space traps the expanding gases, leading to a rapid increase in pressure characteristic of an explosion.

Safety experts stress that by eliminating any one of these five elements, the risk of a dust explosion can be significantly reduced. However, they caution that this approach may not completely eliminate fire risks, highlighting the need for comprehensive safety strategies. The importance of this knowledge cannot be overstated, given the potential for dust explosions to cause severe damage, injuries, and fatalities in industrial settings. Industries particularly at risk include those dealing with wood processing, metal working, food production, and chemical manufacturing.

To mitigate these risks, companies are advised to implement rigorous dust control measures, ensure proper ventilation, regularly inspect and maintain equipment to remove potential ignition sources, and design facilities with explosion relief features. Additionally, training employees to recognize and report potential hazards is crucial in maintaining a safe work environment. Experts also emphasize the importance of conducting thorough risk assessments to identify areas where dust accumulation is likely and implementing regular cleaning schedules. The use of explosion-proof electrical equipment and the installation of spark detection and suppression systems are other recommended preventative measures.

The concept of the Dust Explosion Pentagon is closely linked to confined space safety, as many dust explosions occur in enclosed areas. This connection underscores the need for specialized confined space rescue services in industries where both dust hazards and confined spaces are present. As industries continue to evolve and new materials and processes are introduced, the relevance of the Dust Explosion Pentagon remains constant. By understanding and addressing these five critical elements, companies can significantly enhance their safety protocols and protect their workforce from the devastating consequences of dust explosions. For more detailed information on this topic, interested parties can read about The Dust Explosion Pentagon and Confined Spaces, which provides further insights into preventative measures and safety strategies.